Formulations R&D

Research and Development (R&D) – Overview

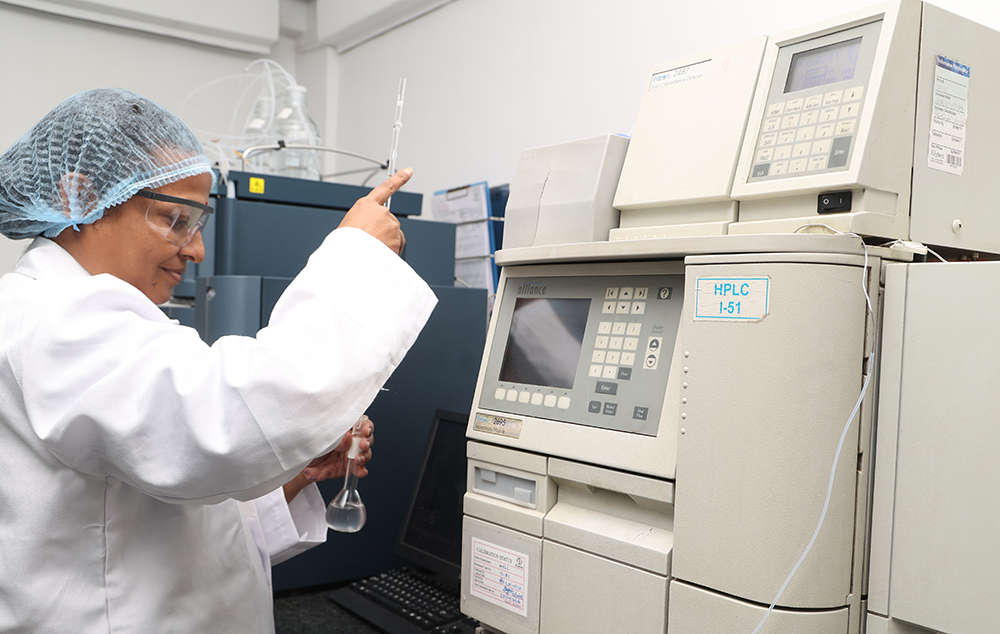

Welcome to Kopran, where excellence in Formulation Research and Development takes center stage. As a technology-driven pharmaceutical leader, we are dedicated to pushing the boundaries of innovation in the industry. Our Formulation Development and Analytical Development departments, supported by cutting-edge laboratories and top-tier technical experts, make Kopran a powerhouse of pharmaceutical advancement.

Emphasizing continuous improvement in processes, quality, and the creation of novel products, Kopran stands at the forefront of technological evolution. Our fully-equipped laboratories facilitate comprehensive physical, chemical, and micro-biological testing, ensuring the highest standards in pharmaceutical development.

Strengths and Capabilities

- Our R&D team’s vast experience spans Modified Release, Novel Drug Delivery System (NDDS), and Parenteral Injections. Their deep knowledge extends to formulation development, manufacturing, and commercialization.

- A dedicated Tech Transfer and team ensures seamless technology transfer and scale-up operations.

- Formulation R&D capabilities cover the design and development of new dosage forms, pre-formulation studies, lab/pilot scale studies, process optimization/validation studies, stability studies, technology transfer of new products, technical support to manufacturing locations, and continuous technology and development upgrades.

- Analytical Development capabilities include the development and validation of various analytical test procedures, finalizing specifications for thorough evaluation of desired quality attributes.

- Expertise spans various therapeutic developments, such as antibiotics, cardiovasculars, antidiabetic, central nervous system, antiprotozoal, anthelmintics, potent drugs, NSAIDs, and other general category drugs.

- Our plant is equipped with R&D lab-scale equipment catering to different levels of scale-up sizes required for developing and commercializing in-house and customer projects.

Key Focus Areas

- Regulated Markets Excellence: Developing products and formulations that align with reference and innovator products is at the core of our strategy for regulated markets. We strive not only to meet but to surpass expectations, ensuring the highest quality and efficacy.

- Swift Site Variations: In critical markets where the approval lead time for variations is traditionally longer. This Our strategic approach facilitates quicker site variations, providing us with the agility needed to respond to dynamic market demands.

- Innovative Dosage Forms: Our commitment to innovation extends to exploring newer and unique dosage forms. Special focus is given to Tablets and Mouth Dissolving Tablets, enriching our product portfolio and offering distinctive value to our customers.

- Strategic Advancement with Amoxy Clav: We are strategically developing Amoxy Clav to provide a significant advantage to our existing Amoxy customer base. This initiative is a testament to our dedication to understanding customer needs and enhancing their experience with our products.

- Formulations and Packaging Development: Our formulation and packaging development initiatives are approached with a holistic mindset. By combining innovative formulations with carefully designed packaging, we ensure that our products not only meet but exceed industry standards.

Explore the world of Formulation R&D excellence with Kopran, where innovation meets precision, and healthcare solutions evolve to meet the needs of partners and clients globally.

Active Pharmaceutical Ingredients

We leverage our experience of 40 years in developing APIs across diverse therapeutic areas and are a leading supplier to generics manufacturers. Our product portfolio includes over 30 APIs across multiple therapeutic segments, Antibiotics, Carbapenems, Macrolides, Tetracycline, Antidiabetics, Anticoagulant, Cardiovascular etc. We are the first company across the globe to develop and manufacture Nitrosamine and Genotoxic impurity free Nitroxoline and awarded Patent…and many more to come.

Research and Development

- WE ARE AN R&D-DRIVEN COMPANY, Run by a highly qualified team of professionals, custom synthesis is performed in accordance with the new generation API requirements. With world class capabilities and technological insight, we add value to the customer by providing High Quality APIs & Customised Services at affordable pricing.

- With our state-of-the-art research centre, we lead the way to pioneer a progressive production model. Our R&D teams focus on the development of APIs and Custom Synthesis, we are excellent in multi-step chemical synthesis with diversified reaction types including the use of delicate chiral molecules and hazardous chemistries. We adhere highest standards of Legal and Regulatory requirements during development of scalable and cost-effective APIs.

- Highly equipped and expert in High End analytical techniques such as HPLC, GCHS, LC-MS, NMR, X-Ray diffraction techniques, DSC, TGA etc to Characterise, Develop and Validate the API molecules, Continuous focus on Process improvements to achieve better quality and efficacy for our existing products.

- R&D Highlights

- Focused on development of Non-Infringing Scalable Technologies

- Expertise in complex classes of Chemistry e.g. Chiral, Macrolide, Tetracycline, Carbohydrate

- Operates in all type of reaction e.g. Acylation, Nitration, BuLi, C-C coupling, Chiral Chemistry and organometallic reactions etc

- Autoclaves from capacity 1.0 Lt to 5.0 Lt

- Capability of handling highly complex and hazardous reactions with utmost safety and efficiency

- Reaction Capabilities from -70°C to 200°C

- State of art facility built for the scale up of products from grams to kilograms

- GMP Scale-up facility Flexibility to accommodate virtually any process requirement for scale up

- Kilo Lab – Combined volume of over 1200 Lits

-

Reaction capabilities

1. C-C Coupling reactions 11. High Pressure Hydrogenation 2. Chiral Synthesis 12. Cryogenic Reactions 3. Alkylation 13. Butyl Li reactions 4. Enzymatic Reactions 14. Oxidation 5 Amination 15. Reduction 6. Friedal Craft Reaction 16. Silylation 7. Chlorosulphonation 17. Halogenation 8. Epoxidation 18. Nitration 9. Beta Lactam Chemistry 19. Protection and Deprotection 10. Grignard Reaction 20. Mannich Base Reaction CDMO Highlights

- Route Selection

- Process Development

- Process Optimization

- Analytical Development

- Technology Transfer

- Impurity Profiling

- Commercial Manufacturing

- Stability Studies

Manufacturing Capabilities

In the pharmaceutical business, the role of manufacturing and operations need to be over emphasised as products affect human lives. In view of this, the Kopran has invested in the highest standards of manufacturing excellence,

Our strategic plant locations in Mahad, Panoli and the pilot plant in Panoli as well as in Mahad to bolster our operational capabilities. At Kopran, our ultimate goal is to deliver high-quality APIs at affordable pricing to customers across the globe.

Our manufacturing facilities are globally compliant API facilities with USFDA, EDQM, ANVISA and other regulatory approvals and adhere to the highest quality standards. Our facilities are equipped to handle everything from large-scale, specialised factories to small-scale, specialty APIs.

We manufacture a range of APIs in dedicated facility including Sterile APIs ( Separate plants for Non Beta Lactams and Beta Lactam molecules)

- 2 API Facility of 27000sqm, 9000sqm and 8500sqm at Mahad – Maharashtra and Panoli –Gujarat

- API facilities successfully inspected & Approved by USFDA, EDQM, EU GMP (France), WHO (Geneva), TGA (Australia), DMA (Denmark), , AIFA (Italy), AFSSAPS (France), MFDS (South Korea) among others

- Dedicated facility including Sterile APIs for Non Beta Lactams and Beta Lactam molecules)

- cGXP compliant facility – High Quality standards with continuous improvement

- Dedicated multistep manufacturing expandable manufacturing facilities,

- Stainless steel and glass-lined reaction vessels ranging from 50 litres to 6000 litres

- Total working capacity 227,000 litres

- Hydrogenation facility with working pressure upto 70 bar

- Reaction Capabilities from CRYO -70°C to high temperature 200°C

- Palletisation and granulation facility

- State of the Art Solvent recovery facility

- Micronizing facility for particle size reduction

- Microbiology testing facility

- In-house Effluent treatment plant with installed capacity for treating >250 KL per day effluent

- Handling highly complex and hazardous reactions with utmost safety and efficiency.

- State of art facility built for the scale up of products from grams to Multi tone.

- Flexibility to accommodate any process requirement for scale up

- EHS – First priority, Safety system and Fire Hydrant System placed in all location